2022

Offcut Factory

Material waste is a prevalent issue in the manufacturing industry.

In Singapore, about 7.23 million tonnes of solid waste was generated in 2019. Amongst which, the recycling rates for stone and ceramic was only at 7%. Most material offcuts that are produced during manufacturing are inevitably left abandoned as industrial waste.

The project sought to understand the current processes of material waste management in the manufacturing sector, as well as the scale of the problem that material waste poses to these individual companies.

Awarded:

Good Design Research by DesignSingapore Council

Team:

Esli Ee

Site visits and interviews

“It’s such a waste to throw, they are all still beautiful.”

- Mr K, design consultant at a natural stone supplier

“Sometimes we don’t know what to do with all these (wood offcuts). We just put them into the container.”

- Mdm A, staff at a woodworking factory

In conversations with the many factories that we visited, the staff spoke about facing the problem of producing a large amount of “material leftovers” or “offcuts” during the manufacturing process, which are often discarded and disposed of through various means.

However, there was also a strong, shared sentiment from them not to see these material offcuts being “wasted”, with a wish to see them being better utilized.

Key insights

1. High disposal costs

We have learnt that factory owners have to pay an exorbitant fee to dispose of their material waste. For example, an owner of a marble factory revealed to us that he had to spend close to five figures to contract movers to dispose of four skips of discarded marble material and offcuts.

One might think that the cost alone would deter him from doing so, but more often than not, it is the only way for factory owners to manage the accumulated offcuts in their premises. They are aware that it is an extremely wasteful practice but see no alternative solution.

2. Unused, but not unwanted

Secondly, due to the sheer volume of materials that they bring in and work with, sometimes they will even have to dispose of still-usable materials.

We saw a parallel to this with the global food waste problem, where perfectly-edible food are thrown away on a daily basis due to over-ordering and excess inventory.

3. Definition of offcut is subjective

Lastly, what constitutes an “offcut” or “waste” can be subjective. To us, an A4-sized marble slab might not be viewed as an offcut. However, for a company that deals primarily with large installation projects, it would considered too small for use and be discarded.

Design opportunity

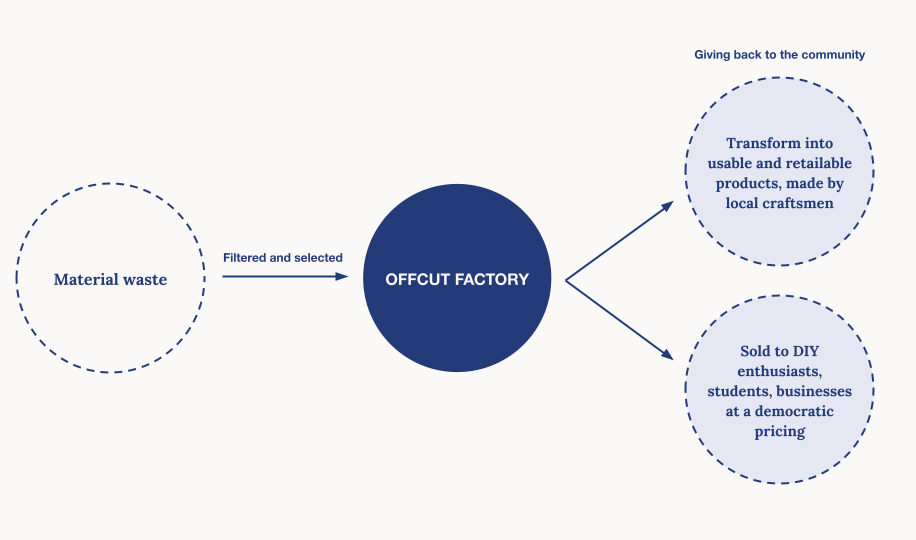

“What if we can create new value by leveraging on the existing know-how of these factories?”

We realised that many of these still-usable offcuts have a beauty of their own and need not be discarded.

In addition, many of these factories have long-established histories and contributions in the local manufacturing industry, with a wealth of domain knowledge and expertise built up over the years.

We thought—what if there was an opportunity to create new value for these material offcuts by leveraging on the existing know-how of the factories?

Co-designing products with craftsmen

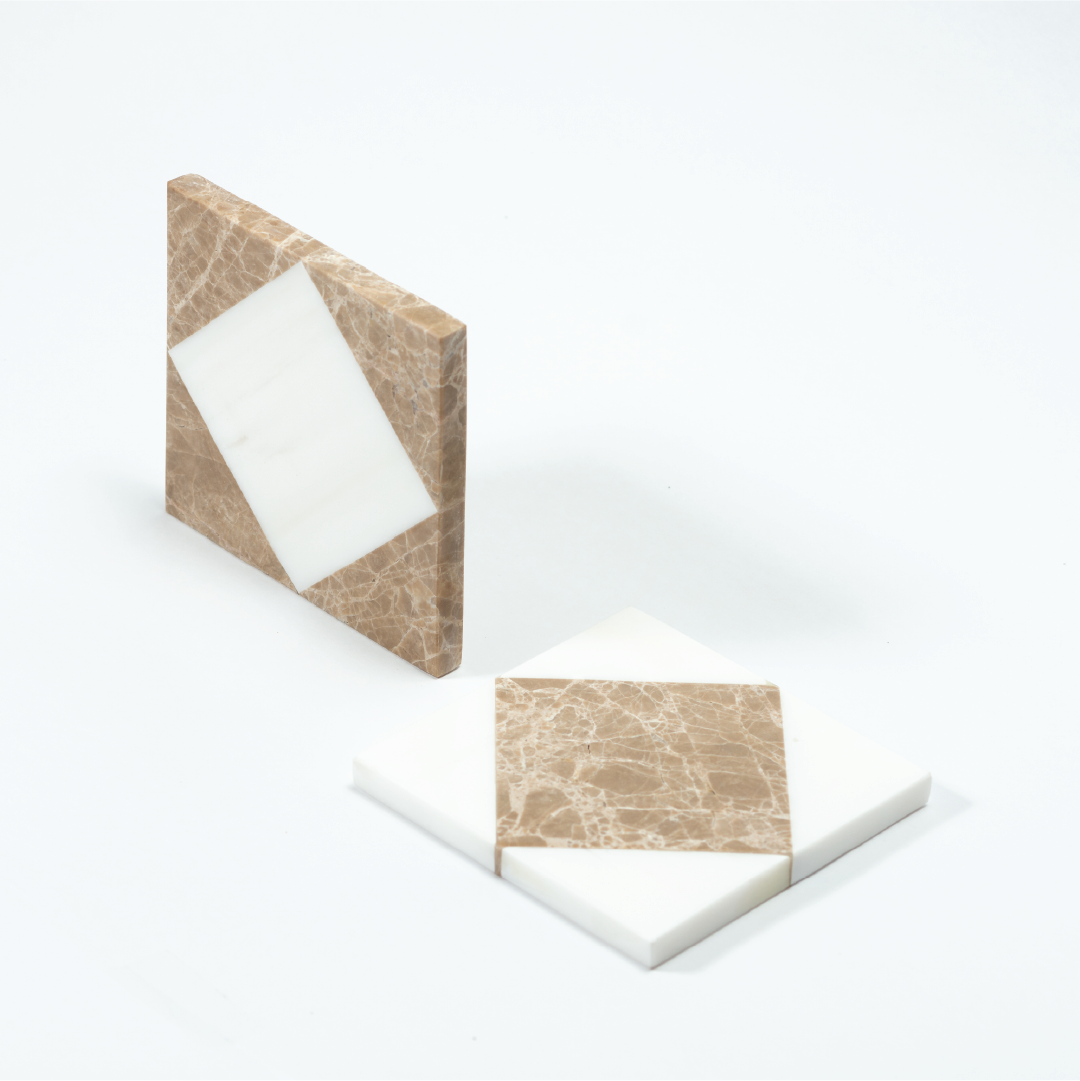

By partnering with local craftsmen and design studio Trigger Design, we launched a series of functional lifestyle objects that are made from discarded material offcuts.

From top-left, clockwise:

- A ruler with its length uniquely derived from a single cabinetry moulding offcut

-

A tape dispenser assembled from varying geometrical wood offcuts

-

A pair of coasters made from leftover marble fragments from commercial installation projects

- A stationery tray crafted from unwanted nyatoh architrave strips

Exhibitions and showcase

As part of our outreach and publicity efforts to spread awareness on the problem of material waste, we designed exhibitions and installations to invite the public to interact with our products and offcuts in-person.

An installation titled “100 Marble Tiles”, where we challenge visitors to identify the 10 rejected tiles from the rest. Upon closer inspection, one realises that the line that seperates accepted and “ïmperfect” marble is extremely blurry.